| Making Plastic

Rings |

I guess most of us

have already faced the need of small rings for one or another reason.

One could simply slice plastic tubing, but in practice it is virtually

impossible to run the blade perfectly parallel to the first cut - the

result is a skewed ring. And besides, you have to find a piece of

tubing of the exact diameter and wall thickness you are looking for...

There are photoetched alternatives, but they may be too thin.

Furthermore, few things can beat the flexibility that styrene parts and

liquid glue give us.

This is an old trick that I've been using for years to make plastic rings. I'm sure you will get good results at your first try. Not to mention that you won't waste a single buck to do it at home.

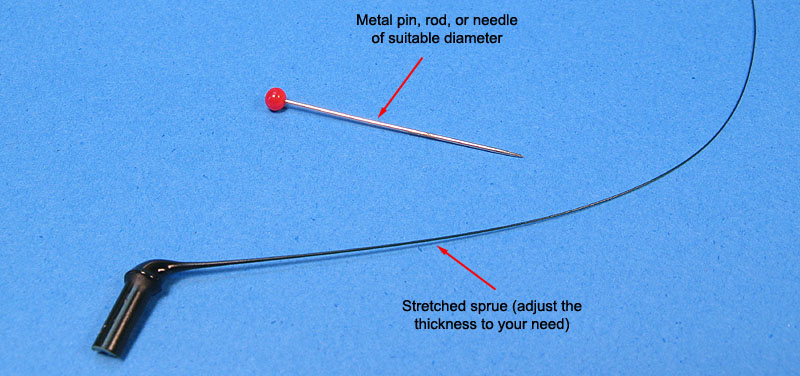

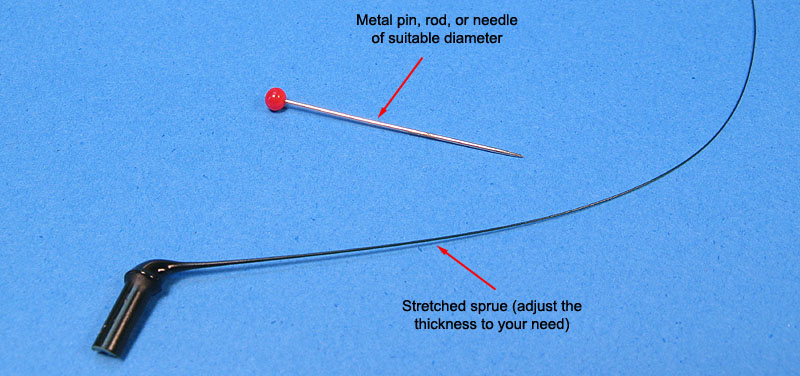

Start with a metal pin, rod or a needle with the same diameter of the internal diameter or the rings you need. Next, prepare a good length of stretched sprue, trying to achieve the thickness of the ring you want:

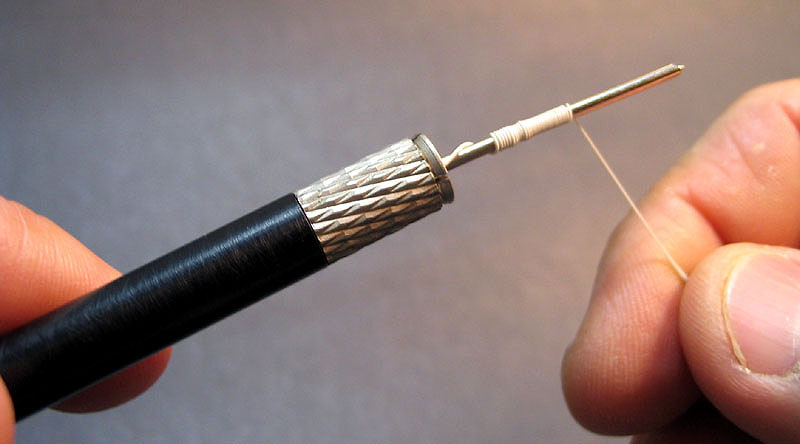

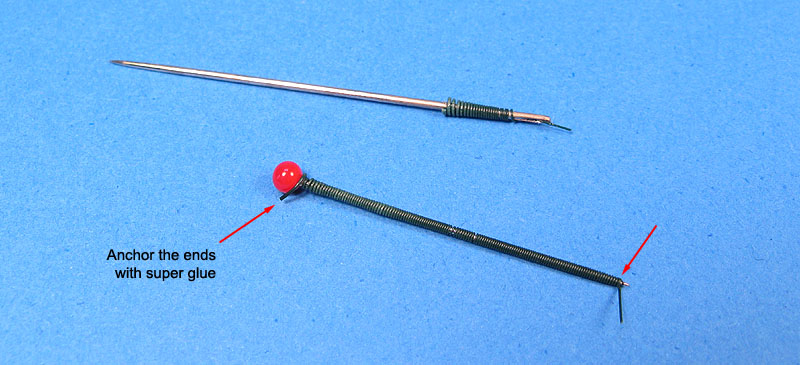

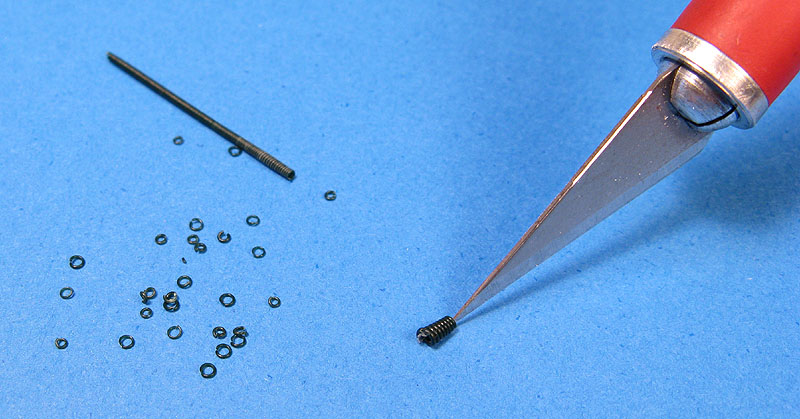

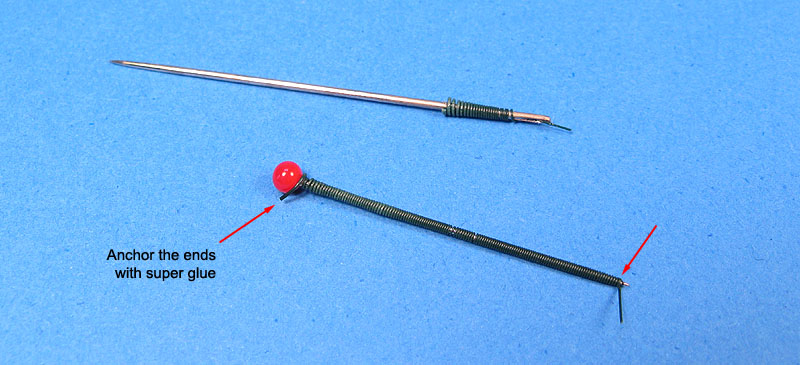

Now coil the sprue around the pin. I generally use brass pins with 1.0, 1.3, 1.5, 2.0 and 2.5 mm diameter for most cases, but for small scales it may be necessary to use syringe or sewing needles. The ends must be strongly fixed so that the stretched sprue doesn't loosen during the process:

Next step: cook it. About a minute in boiling water is more than enough:

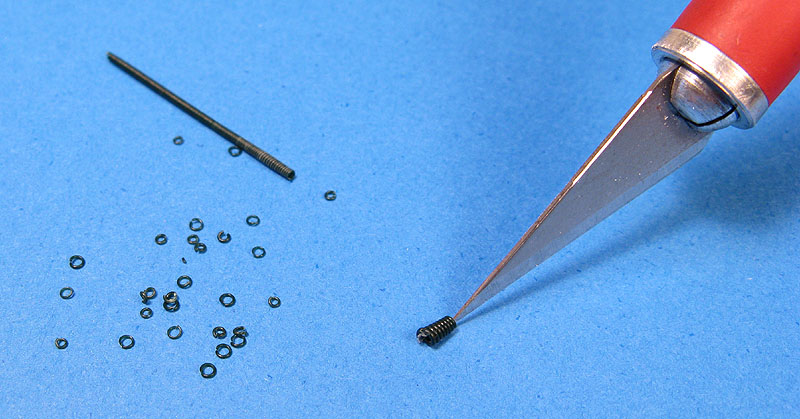

Remove it from the water, wait it to cool and extract the coil from the metal pin. You may need to scrap the ends with a hobby knife. Now the coil will be permanently shaped the heat action:

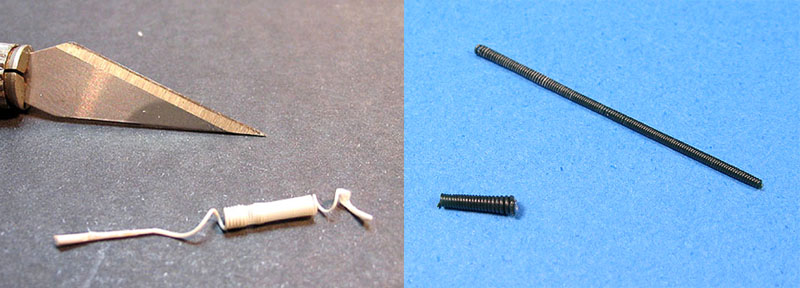

Take a fresh blade and cut longitudinally all the way through the plastic, as shown in the pictures below. Do it over a hard surface of a piece of glass:

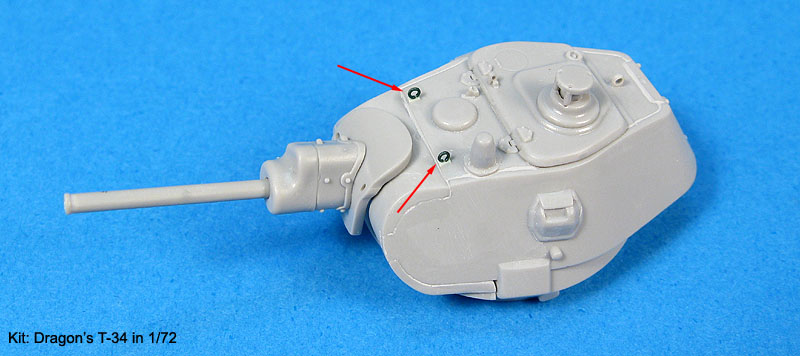

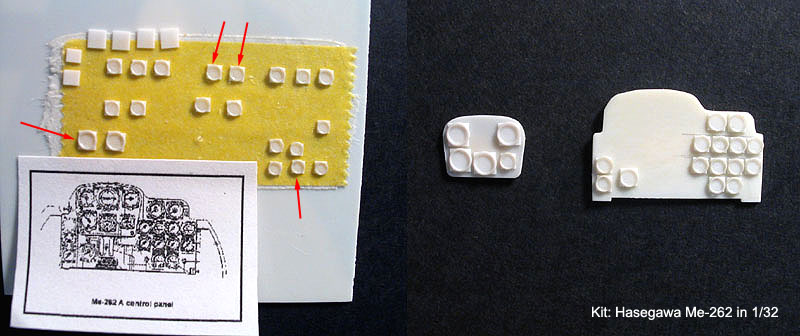

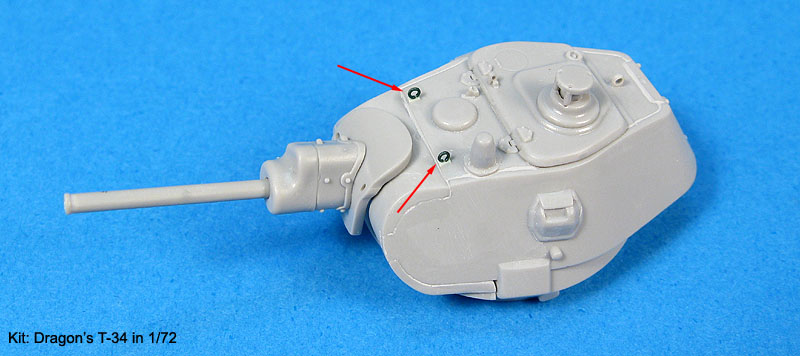

In a matter of minutes (literally) you get bezels for many models/applications:

There are countless applications for this technique. Here are a couple obvious application examples:

I've also been using this for hatches in 1/700 ship models, hooks in AFV, mass balances in aircraft, and the list goes on.

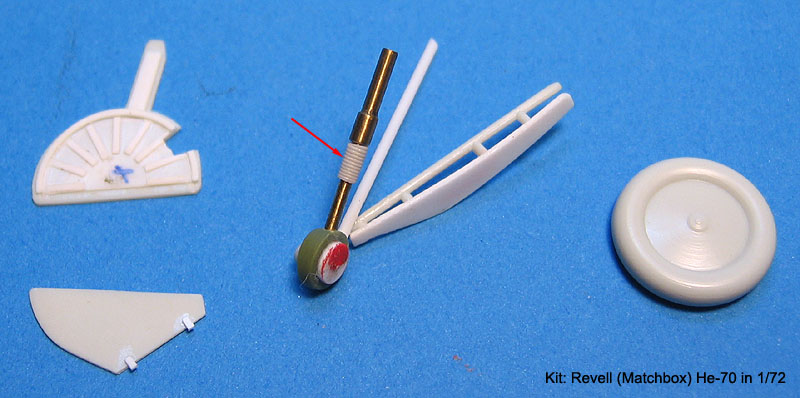

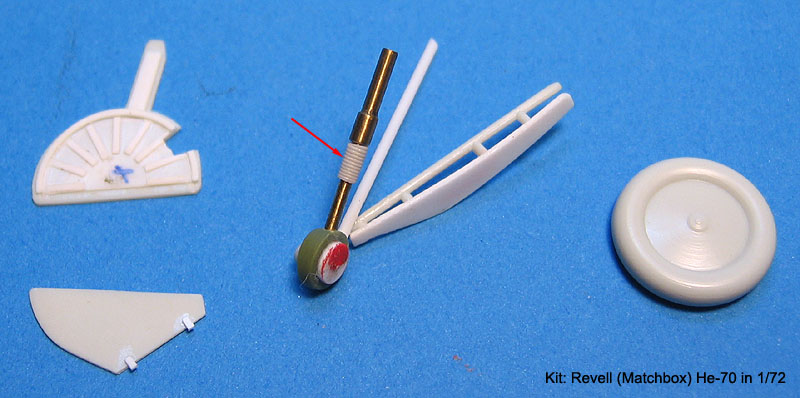

Sometimes, all you want is the coil itself, not the rings, such as in oxygen hoses, engine plumbing, etc. Here is the rubber boot of my 1/72 Heinkel He-70 landing gear made with this method:

And if you want to be a rivet counter, the outer diameter of the rings will be the diameter of the pin plus twice the thickness of the stretched sprue. I hope you find this tip useful.

Rato

Marczak

© 2009This is an old trick that I've been using for years to make plastic rings. I'm sure you will get good results at your first try. Not to mention that you won't waste a single buck to do it at home.

Start with a metal pin, rod or a needle with the same diameter of the internal diameter or the rings you need. Next, prepare a good length of stretched sprue, trying to achieve the thickness of the ring you want:

Now coil the sprue around the pin. I generally use brass pins with 1.0, 1.3, 1.5, 2.0 and 2.5 mm diameter for most cases, but for small scales it may be necessary to use syringe or sewing needles. The ends must be strongly fixed so that the stretched sprue doesn't loosen during the process:

Next step: cook it. About a minute in boiling water is more than enough:

Remove it from the water, wait it to cool and extract the coil from the metal pin. You may need to scrap the ends with a hobby knife. Now the coil will be permanently shaped the heat action:

Take a fresh blade and cut longitudinally all the way through the plastic, as shown in the pictures below. Do it over a hard surface of a piece of glass:

In a matter of minutes (literally) you get bezels for many models/applications:

There are countless applications for this technique. Here are a couple obvious application examples:

I've also been using this for hatches in 1/700 ship models, hooks in AFV, mass balances in aircraft, and the list goes on.

Sometimes, all you want is the coil itself, not the rings, such as in oxygen hoses, engine plumbing, etc. Here is the rubber boot of my 1/72 Heinkel He-70 landing gear made with this method:

And if you want to be a rivet counter, the outer diameter of the rings will be the diameter of the pin plus twice the thickness of the stretched sprue. I hope you find this tip useful.