| Making Rolled

Ropes & Hoses |

I found a simple way to overcome these problems and produce reasonably convincing ropes and hoses in smaller scales. Let me show you how.

The idea is quite simple: to extrude putty to the desired shape. All you need is a disposable syringe and a heavy duty (veterinary or similar) needle which fits the syringe. These needles are not beveled like hypodermic ones, which is perfect for this trick (if you're going to use one which is, cut the beveled end flat first). Insert a small amount of putty in the syringe and squeeze it throughout the needle, just like when applying any liquid matter. The only difference is that you must push it harder (much harder!). That's why you have to use needles of larger gauges, I mean, smaller needles will make it impossible to the putty to run through it (unless the putty consistency is so liquid that the method won't work).

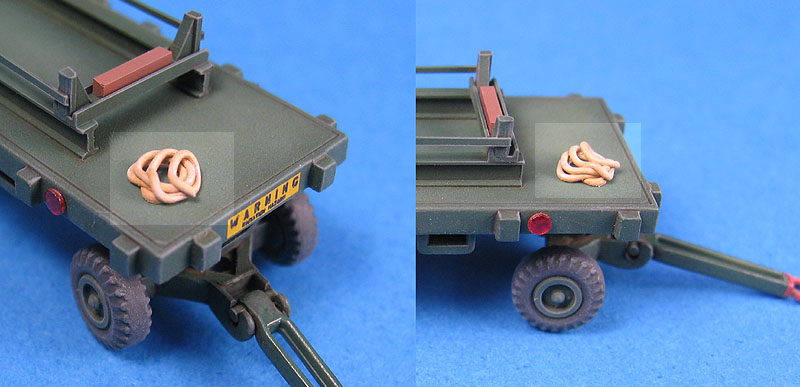

You've got it. We want to extrude the putty pretty much like making spaghetti. Use a piece of glass or a non sticking flat surface (backing layer of adhesive paper will do) to deposit the putty as you go. The shape of the rope/hose produced depends on the movement you impose to the needle. Overlapping circular movements will result stacked rolls of rope, but you can go as crazy as your garden hose.

Let the putty dry overnight and carefully detach it from the surface. There you have it: small stacks of rope molded in virtually any shape. I like to use Revell Plasto body putty, but similar brands will work too. In a single working section with the method you will produce at least a dozen or so of these little hoses, so don't bother to clean the syringe/needle. Although the results don't have the so characteristic texture of ropes (hoses don't have it, though), the method will naturally capture the sag due to the hose/rope own weight - something difficult to do with wire (one of the high points of the technique, in my opinion).

Of course you can vary the diameter of the hose by changing the neegle gauge. The only care you must have is during handling the parts, obviously very fragile. I like to use this technique in 1/72 scale, and sure it will also work in 1/48. For larger scales, I think stitching lines, cooper wire and soldering iron will do a better job, particularly if you're after some surface texture.

I hope you find this tip useful.