| Review Sagyma SW770 double action professional airbrush |

| Summary | |

| Description:

|

-

Gravity feed double action airbrush with built in pressure regulator

(0.25 mm fluid nozzle) |

| Scale:

|

- N/A |

| Price:

|

- approx. 90 USD |

| Contents

& Media: |

-

Acrylic case containing one airbrush, hose adapter, nozzle wrench

and a one page instruction panflet |

| Advantages: |

-

Good overall quality construction - Built in pressure regulator - 0.25 mm nozzle |

| Disadvantages | -

Key parts made of soft brass. - Unnecessarily large fluid reservoir for detail painting - No extra needle included - Visible wear of parts after one year of use |

| Recommendation: |

-

Recommended |

First look

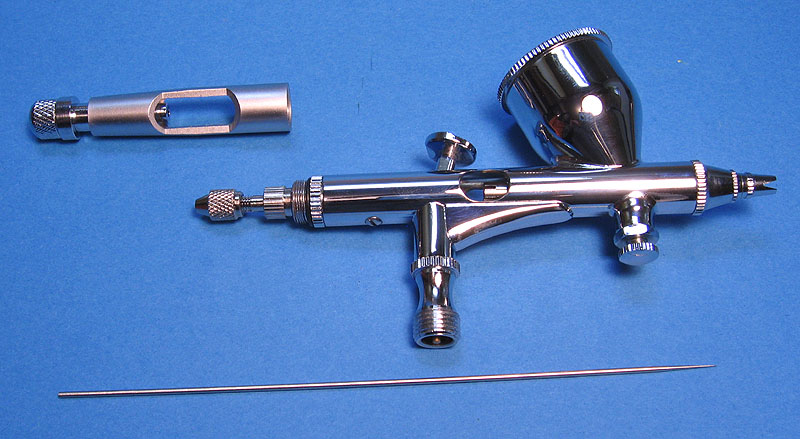

If you ever wondered about an Iwata-like airbrush, costing

one third of its price, I think I've just found it. This is a new

airbrush called Sagyma model SW770. Yep, you guessed... made in China.

However, this is a fairly good product. In fact, except for the

lateral opening in the main body and a smaller nozzle, it seems a copy

of the Iwata HP-C Plus.

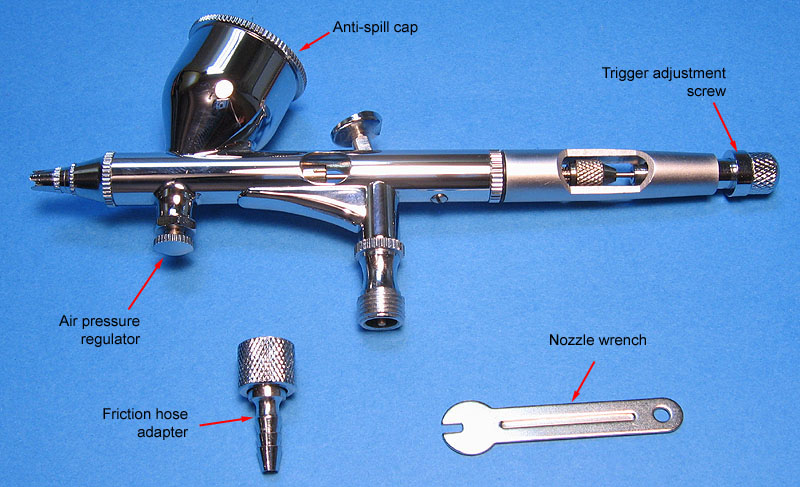

The product comes in a nice acrylic case with contents

protected by high impact foam. It comes with a complete airbrush, a

screwless hose adapter and a nozzle wrench. The quality of the tooling

is very high, and unless you look very closely, you will believe it is

a Iwata.

The

main body of the airbrush is made of chrome plated parts, with the aft

handle in

Aluminum, ensuring it completely safe to spray lacquer thinners. The

air valve screw is the same of Tamiya Spray-Work series, so if you have

a Badger hose, you'll need the Tamiya adapter (item #93010).

The other option is to use the adapter that comes in the set for

friction fitted hoses. The needle has a high pitch adjusting screw at

the end of the handle, which is a welcome help to spray constant width

lines. Of course you can leave it open to allow full amplitude trigger

stroke, or take it off the airbrush to remove the needle without the

need to unscrew the aft handle.

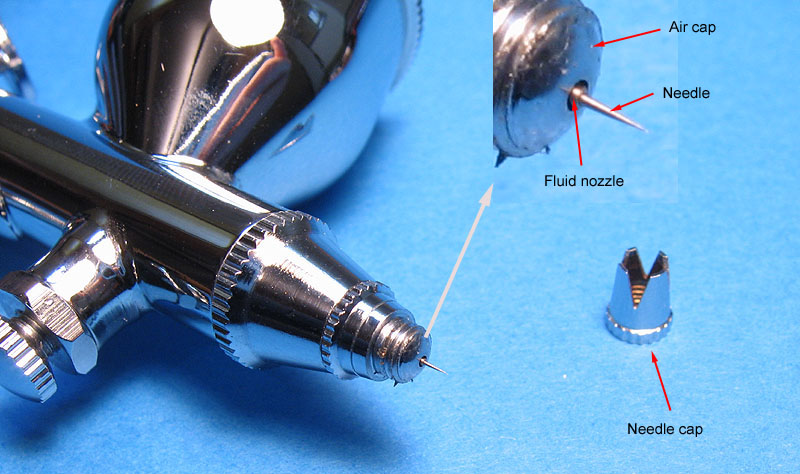

After the dealer, the nozzle/air cap system should be self-centering

(it is not!). Like the

Iwatas, the nozzle cap has only a protective function, avoiding a

complete exposure of the needle. And since the nozzle is 0.25 mm, the

needle is very fragile at its end. Too bad an extra needle is not

provided. A common feature of high performance airbrushes is their

ability to spray without the needle cap attached, something a Testors

or a Badger airbrush cannot do (except for the Sotar 20/20). This

feature is particularly important to spray very fine lines, since the

needle cap always produce some turbulence when the atomized paint

leaves the nozzle.

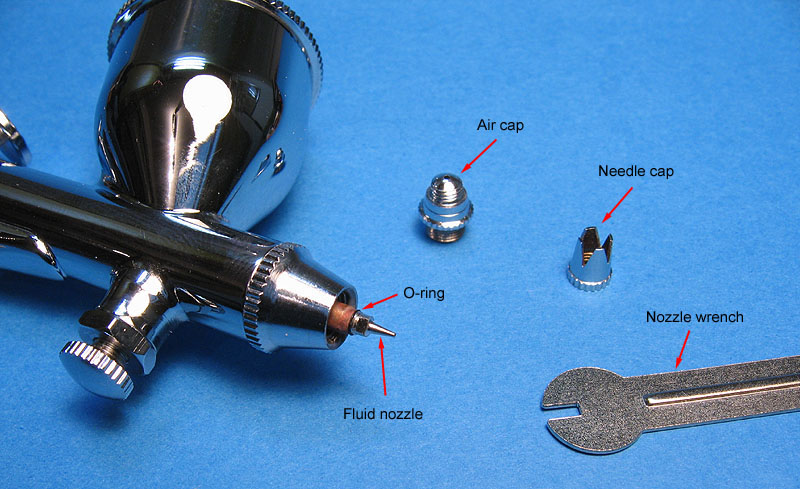

Removal of the air cap reveals the fluid nozzle, which is

sealed by an o-ring. I don't like this type of seal, but the

manufacturer assured me it is thinner resistent. They also advised me

that it's not necessary to remove the nozzle after each painting

section. Since it is a very delicate part, you should remove it only in

case of clogged nozzle, or occasionally for a complete clean-up.

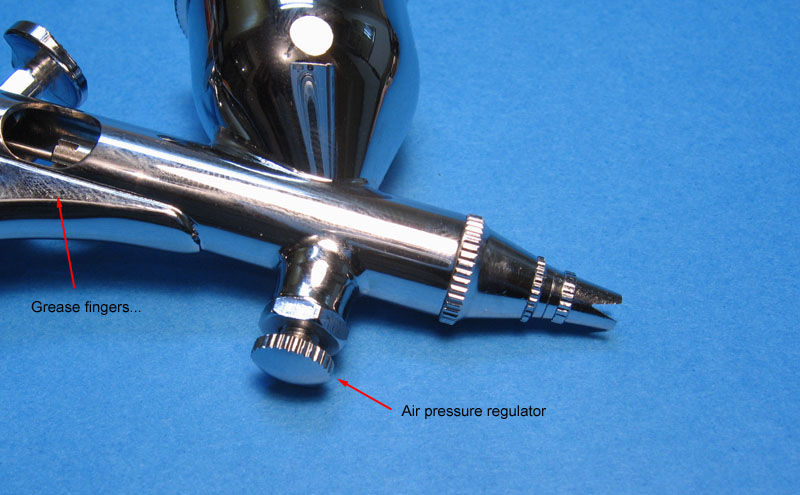

A usefel feature of this airbrush, copied from the Iwata as well, is the built in pressure regulator. Basically, it is a valve installed inside the airbrush responsible for controling the air pressure the air reaches the air opening. Altough you can't read the exact pressure, this is a very handy device: you set your compressor/cylinder pressure (maybe slightly higher than usual, say 15-20 psi), and perform a quick fine tunning for the mix you have just loaded to your gun, without taking your eyes off the bench. You can even shut the air completely. Leaving it full open, you have the same pressure you adjusted in your compressor/cylinder. Note that (particularly in the case of compressed air) the pressure you set in your compressor regulator is not exactly the same that your airbrushing valve is delivering (head loss, technically speaking).

Performance

I played a bit with this airbrush for this review. Having

tried a Iwata a few times before, I can tell you the SW770 perform

pretty much like that, except for an annoying click when the air valve is

triggered. It weights about the same of a Badger 100, and the needle

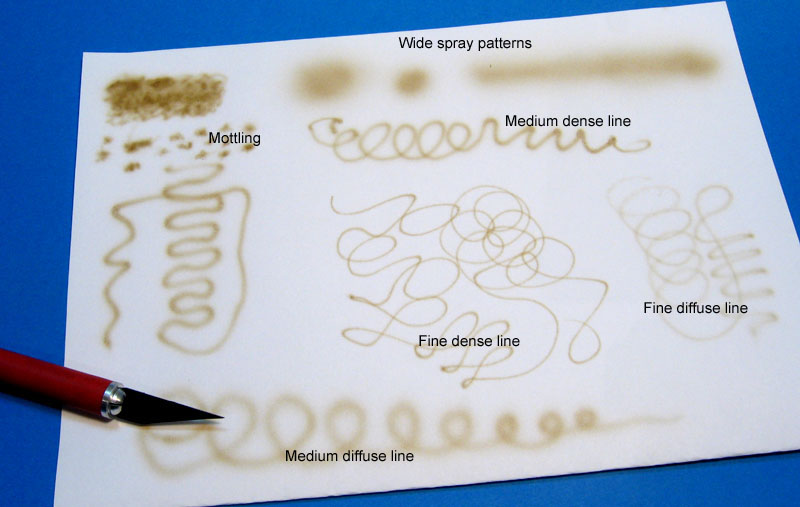

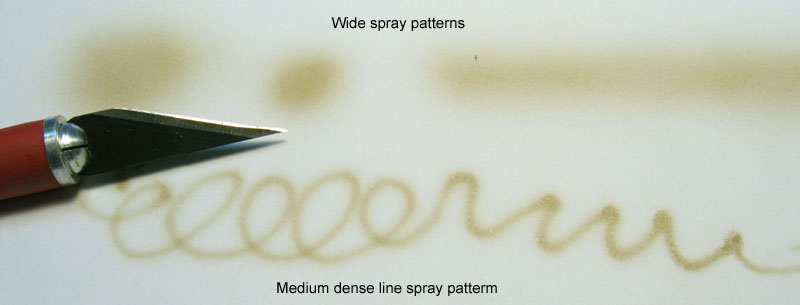

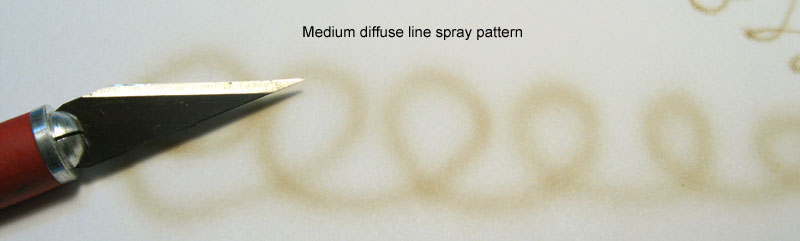

action is very smooth. I made some tests using water soluble inks (my

standard test for airbrushes) to see how it works when pushed.

On my very first trial, I found this tool produce an excellent

atomization pattern for a wide range of pressures. I started with 8 psi

and increased the pressure up to 25 psi, and the gun performed very

well in all tests. I was able to paint very fine lines by removing the

needle cap, and almost touching the surface with the needle (watch out,

don't bend it!). More than the spray patterns obtained (agreed, they

could be done with a number of other brands), what impressed me the

most was the easiness with that I sprayed fine lines and mottlings.

Honestly, way easier than with my trusty Badger workhorse.

Cleaning

Conclusions

(ed: text amended after one year

using this gun)

After using this airbrush for a year, I can add a few comments on the SW-770. First, it does have a good performance. No doubt. But to access such performance, you must:

- Get used with the annoying click of the air valve.

- Wait for proper stars alignment so that the fluid nozzle is aligned with the air cap orifice.

- Cross your fingers that your needle belongs to a batch which was well manufactured (mine wasn't, but the replacement ordered later was better).

Talking seriously, the fluid nozzle is not self centering. In fact, it is self un-centering. The screw threads in the fluid nozzle and airbrush body don't match very well, and are manufactured with loose tolerances. The important parts are manufactured with soft alloy brass, which is not recommended for precision fitting parts (yes, I'm a mechanical engineer). The solution is the rubber ring, used to allow the proper tightening and seal everything. That's why it is difficult to align the nozzle. And those rubber seals last two or three baths in lacquer thinner... no more. I recommend you to find a centered position for the nozzle and avoid disassembling the fluid nozzle as much as possible after that.

This is not a bad airbrush. It just is not manufactured with the same precision level and material quality of other mainstream brands, consequently, it won't last long. You simply get what you pay for... so, don't think of it as a gun which will last 20 years like your old trusty Badger. This one won't...

You can find more info about this airbrush with the Brazilian dealer Yamar Tools & Machines (where I got mine) through their web-site or by e-mail.

Rato Marczak © 2007-2010